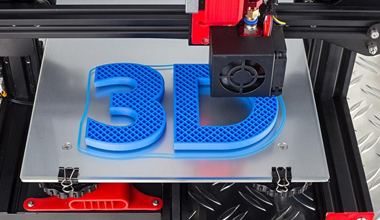

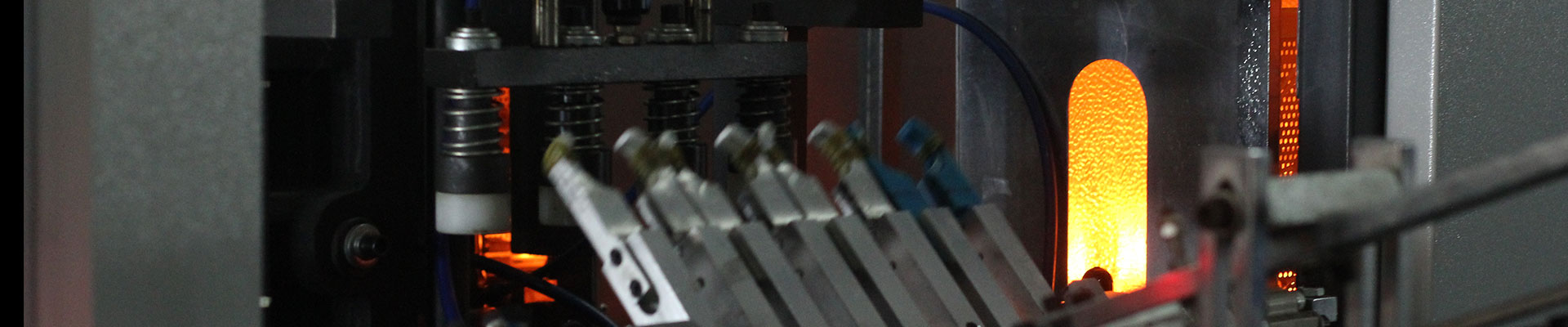

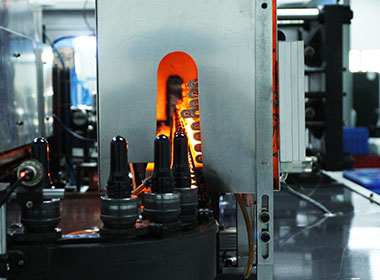

For the blowing technolog, such as Stretch Blow Molding, Extrusion Blow Molding . Injection Bolw Molding

Plastic Bottle Professional Manufacturer

- Prompt & Accurate Quotation

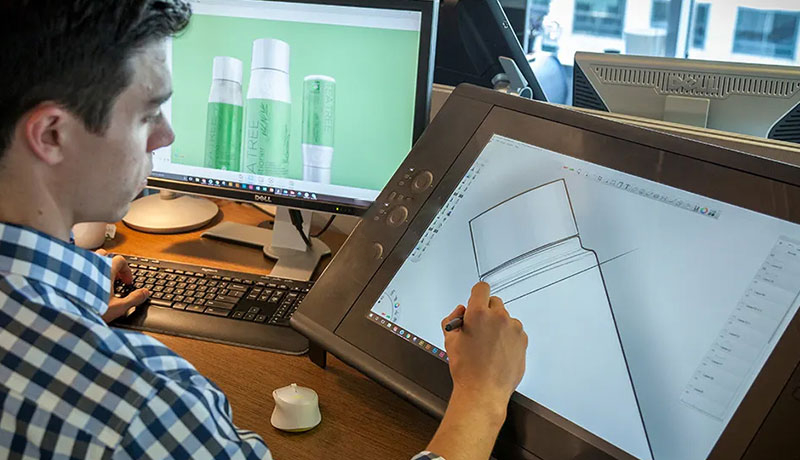

Creating Innovative Packaging Daily

There is no doubt that creativity is the most important human resource. Without creativity, there will be no progress.Innovation on the one hand to improve the utilization factor of material production, reduce investment; on the other hand through the introduction of advanced equipment and technology to reduce costs. sanle provides world-class package and product design and graphic design services geared to increase sales and reduce total packaging costs for our customers.

Process of blowing

- 1

Stretch Blow Molding:

Preform injection--Mold closes---Stretch and Bolw station---Product Ejection

- 2

Extrusion Blow Molding:

Parision Drops---Mold closes---Excess Trimmed---- Mold Open---- Bottle Removed

- 3

Injection Bolw Molding:

Preform injection--Mold closes---Stretch and Bolw station---Product Ejection

SANLE, currently there are two factories in normal operation. A total of 21 production lines are in normal operation, and there is a trend of growth every year. Among them, there are 9 dedicated blow molding machines, 13 injection molding machines, fully automatic robotic arms, printing machines, lid assembly machines, etc., and there are plans to add new equipment every year.The monthly capacity of a production line reaches 4500000pcs

21Article

Production line

9set

Blow molding machines

13set

Injection molding machines

4.5Million pcs

Monthly capacity of a production line

- ISo 9001 (quality) certification

- ISo 14001 (environmental management)

- Leona TM 1300S

- FDA

- BSCI

- SMATEE

| Material | Clarity | MVTR* | O2** | CO2** | Impact Strength | Recycle Code |

| PET (Oriented or Stretch Blown Polyethylene Terephthalate) | Excellent | 2.0 | 75 | 540 | Good | 1 |

| HDPE (High Density Polyethylene) | Poor | 0.5 | 4,000 | 18,000 | Good | 2 |

| PVC (Polyvinyl Chloride) | Good | 3.0 | 150 | 380 | Fair | 3 |

| PP (Polypropylene) | Poor | 0.5 | 3,500 | 7,000 | Fair | 5 |

| PS (Polystyrene) | Excellent | 10.0 | 6,000 | 18,700 | Poor | 6 |

| PLA (Polylactide – Oriented/Stretch Blown bottles) | Very Good | 18-22 | 38-42 | 201 | Good | 7 |

High Density Polyethylene----HDPE

High-density polyethylene (HDPE) is a white powder or granular product. It is non-toxic, tasteless, crystallinity is 80%~90%, softening point is 125~l 35℃, service temperature can reach 100℃; hardness, tensile strength and creep are better than low density polyethylene; wear resistance, Good electrical insulation, toughness and cold resistance; good chemical stability, insoluble in any organic solvents at room temperature, resistant to corrosion by acids, alkalis and various salts; the film has low permeability to water vapor and air, and absorbs water Low resistance; poor aging resistance, environmental stress crack resistance is not as good as low-density polyethylene, especially thermal oxidation will reduce its performance, so antioxidants and UV absorbers must be added to the resin to improve this deficiency. High-density polyethylene film has a lower heat distortion temperature under stress, so pay attention to it when applying it.

Low Density Polyethylene----LDPE

Low-density polyethylene is also called high-pressure polyethylene, often abbreviated as LDPE. It is milky white, tasteless, odorless, non-toxic, waxy particles with matt surface. The density is 0.91g/cm3-0.93g/cm3, which is the lightest variety in polyethylene resin. It has good flexibility, extensibility, electrical insulation, transparency, easy processing and certain air permeability. It has good chemical stability, alkali resistance and general organic solvent resistance.

Polypropylene-----PP

Polypropylene is a polymer formed by addition polymerization of propylene. It is a white waxy material with a transparent and light appearance. The density is 0.89~0.91g/cm3, [1] It is flammable, with a melting point of 165℃, softening at around 155℃, and the use temperature range is -30~140℃

[2] It is resistant to corrosion by acids, alkalis, salt solutions and a variety of organic solvents below 80℃, and can decompose under high temperature and oxidation. Polypropylene is widely used in the production of clothing, blankets and other fiber products, medical equipment, automobiles, bicycles, parts, pipelines, and chemical containers. It is also used in food and pharmaceutical packaging.

Polystyrene-----PS

It is a colorless and transparent thermoplastic with a glass transition temperature higher than 100°C. Ordinary polystyrene resin is a non-toxic, odorless, colorless transparent particle, a glass-like brittle material, and its products have extremely high The transparency, light transmittance can reach more than 90%, good electrical insulation performance, easy coloring, good processing fluidity, good rigidity and good chemical resistance. The disadvantages of ordinary polystyrene are its brittleness, low impact strength, stress cracking, poor heat resistance and boiling water resistance.

Polyethylene terephthalate-*-PET

1. It has good mechanical properties, impact strength is 3~5 times that of other films, and good folding resistance.

2. Resistance to oil, fat, dilute acid, dilute alkali, and most solvents.

3. The heat resistance of pure PET is not high, and the heat distortion temperature is only about 85°C, but it is greatly improved after strengthening. The mechanical properties of PET reinforced by glass fiber are similar to engineering plastics such as PC and PA, and its heat distortion temperature can reach 225℃; PET has good heat aging resistance, and its embrittlement temperature is -70℃, and it still has a certain temperature at -30℃. Toughness; PET is not easy to burn, the flame is yellow, and burning oil drips.

4. The gas and water vapor permeability is low, and it has excellent gas, water, oil and odor resistance.

5. High transparency, can block ultraviolet rays, and good gloss.

6. Non-toxic, tasteless, good hygiene and safety, and can be directly used for food packaging.

Squeeze bottle needs every day in most place.

Such as food, pet care, health and beauty industry, wash bottle chemistry chemical bottle, pharmaceutical industry and used in the foods ervice industry, therefore must comply with all kinds of conditions, squeeze the bottle must be soft enough, with the appropriate pressure to release the dripping, crevasse or crumb of contents, and must also provide solid, firm the two sides of the protection of the container, the squeeze bottle appearance elegant, convenient, save time. Convenient for activities greatly custom printed squeeze bottles, custom squeeze bottles, custom squeeze sauce bottles, custom condiment squeeze bottles, small squeeze bottles, squirt bottles chemicals, squeeze bottle caps, lotion squeeze bottles are easy to operate, even for little hands soft and supple, at the beginning of one hand cover (for example, flip, disc cap, and powder pump... ) make it easier to allocate, in this fast-paced world, plastic squeeze bottle is very convenient, because the squirt bottles chemicals, lab wash bottle, lab squirt bottle, drinks, condiments, or health and beauty farce bottle squeezing action and allocation of the nozzle to reduce the confusion, reduces the case with the use of so as not to waste. When it comes to creating custom labels for dropper bottles and squeeze bottles, it’s important to work with a manufacturer and supplier that can provide high-quality printing services. As professional plastic squeeze bottles, lab wash bottle, lab squirt bottle, and plastics squeeze tubes suppliers, SANLE is recognized for having the most complete families of squeeze bottles from the smallest sample sizes to one-liter options, and many custom sizes in between, Finding oem plastic squeeze bottles suppliers and squeeze bottle manufacturers? Contact us to know more!

CUSTOM SQUEEZE BOTTLE MANUFACTURERS

Choose high quality when choosing high-quality plastic, LDPE, HDPE, and PET plastic squeeze bottle is very durable, and there are a large number of spot supply, choose the size of the bottle, the cap shape, and distribution, to enhance your product line, no matter the bottle need high-temperature resistance, resistance to ultraviolet ray, prevent leakage or prevent children, due to the plastic weight and long service life, so they are a kind of economic and efficient packaging solutions, the long-term wholesale ordering and manufacturing. As one of the leading OEM plastic squeeze bottles, lab wash bottle, custom squeeze sauce bottles, custom condiment squeeze bottles, lab squirt bottles, small squeezable bottles, and plastic squeeze tubes suppliers, Sanle OEM plastic squeeze bottles suppliers, offering a one-stop boutique service. We support you throughout the entire process from design selection and development all the way through to after-sale service.Finding the right OEM dropper bottle manufacturer and plastic squeeze bottle supplier is essential for businesses that want to create custom labels for dropper bottles and squeeze bottles. OEM dropper bottles are a popular choice for many businesses because they are affordable, customizable, and easy to use.When it comes to finding the right OEM dropper bottle manufacturers and squeeze bottle suppliers, there are several factors to consider. First, it’s important to look for a manufacturer and supplier that has experience in the industry and a good reputation. It’s also important to make sure that the supplier has the right materials and supplies to meet your needs.Once you have found a few potential squeeze bottle or dropper bottle suppliers, it’s important to compare their prices and services. Make sure to ask about their turnaround times, shipping options, and any additional services they may offer. It’s also a good idea to ask for samples of their work so you can get an idea of the quality of their products. When it comes to creating custom labels for dropper bottles, it’s important to work with a manufacturer and supplier that can provide high-quality printing services. It’s also important to make sure that the printing process is done correctly so that the labels are durable and long-lasting.Finally, it’s important to make sure that the manufacturer and supplier you choose is reliable and trustworthy. Ask them about their customer service policies and make sure to read customer reviews before making a final decision.Finding the right OEM dropper bottles manufacturer and squeeze bottle supplier is essential for businesses that want to create custom labels for dropper bottles and squeeze bottles. By taking the time to research potential suppliers and compare their services, businesses can ensure that they get the best value for their money.