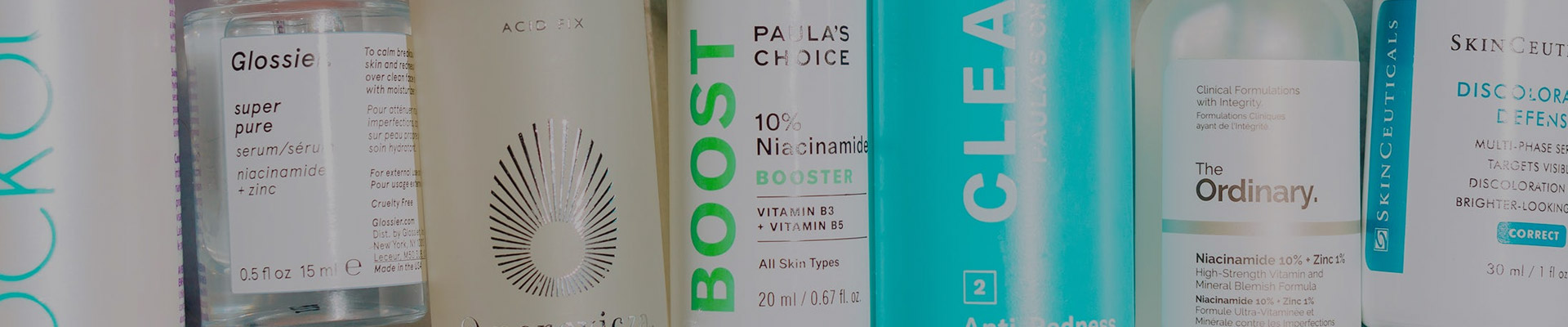

Definition:

Steel (or copper, thermoplastic) intaglio plates are used for pad printing of the plastic squeeze bottles. The surface transfer head made of silicone rubber material is used to immerse the ink on the gravure printing into the surface of the transfer head, and then press it on the surface of the desired object to print text, patterns, etc.